|

||

|  | |

|

||

‘

‘

|

|

‘

‘

‘

|

‘

‘

|

‘

‘

Case Example: Lancer Evolution

where the exhaust is situated at the front of the car, every bit

of weight reduction there helps a lot in improving the handling

of the cars cornering characteristics. Every bit helps for you to

gain that extra edge over your rivals. |

Pictured:@EVO Outlet

(Dump Pipe)

|

|

Genuine@3.05kg |

TOMEI POWERED EXPREME@1.75kg |

| Another example of the product concept designs that TOMEI has developed for the best performance and looks, our Exhaust system for the Subaru Impreza WRX models GDB C/D/E/F. |

| Pipe Diameter. | |||

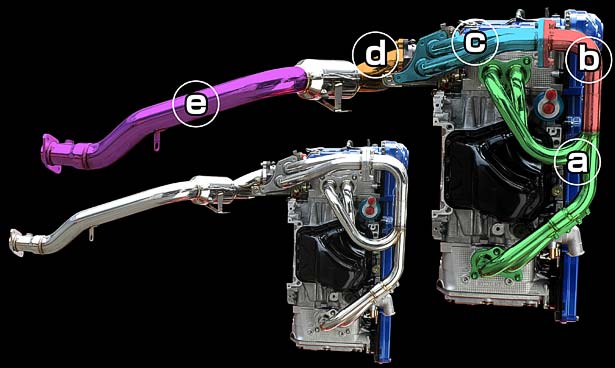

| A | Main Pipe | 38.0mm φ |

From

the exhaust port up to the gathering section (B), the pipes diameters

are 38Σthis has sucessfully raised the exhaust flux for a smoother

flow. |

| B | Gathering Pipe | 42.7mm φ | By making it

wider helps with flow without impairing torque. This size was found

to be the ideal pipe diameter which gives the best improvement of

power. |

C |

Turbo Support Pipe | 42.7mm φ | This helps the

exhaust flow from the turbine, by improving this section you can

then maximise the turbos potential efficiency. |

| D | Outlet | 75.0mm φ | Optimised design

for increased performance and efficiency. |

E |

Following the Catalizer | 75~70~65mm φ | To have the power & torque be more better balanced a pipe with 3 stages of diameters was adopted. |

| Angles in the bend | ||

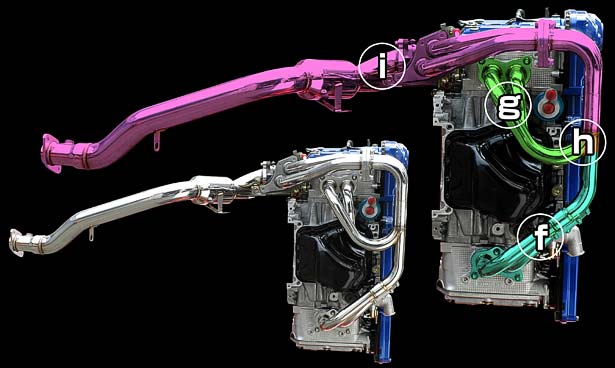

| f | Left Block Side | Increased

efficiency and designed to be made as straight as possible. |

| g | Right Block Side | The

right section extractors have been specially designed for optimum

performance whilst preventing the thermo heat from effecting the

oil pan (sump) temperature. |

h |

Merging Section | The designates

the confluence point as possible limit acute angle, keeps flowing

together the exhaust of each bank smoothly. |

| i | Following the Outlet Pipe | Attention to

detail and calculating the best ways to maximise exhaust flow efficiency,

we have taken all aspects into consideration such as clearance and

operating efficiency of each section. |